Lunac 2+ applied to heavily loaded sliding machine parts

Originally Lunac 2+ was developed for this specific task by means of the special latttice and modified high technical ceramic content, to obtain a reduced coefficient of friction and superb anti-galling properties. This resulted in a very low adhesive wear characteristic (see the adhesive wear diagram), in combination with (av. 25%) reduced friction in many systems. Lunac 2+ on ditto coated faces offers one of the best tribological improvements to parts that are normally nitrided. Not only sliding parts which encounter adhesive |

as well as abrasive wear, but also slightly moving/vibrating parts that suffer from tribo-oxidation and fretting will behave as massive ceramic parts in the case they are coated with semi-ceramic Lunac 2+. The major advantages are the different and easier (cost saving) manufacturing procedures and the presence of ductile metals beneath the coating. Fairly often, machine concepts that cannot or hardly be lubricated turn into a feasible design because of the non-galling Lunac 2+ coatings. |

(Above) the service time of this (HRc 72) Lunac 2+ coated stainless steel (HRc < 30) piston with seals has indefinately been extended because still no measurable wear can be recorded after 3 years. The seals ran in withing .5 years (> 75 µm/ 3 mil) and the original stainless steel surface started suffered from galling within a few weeks. Right: the interior of this stainless steel cylinder valve (food dosing installation) has been coated with Lunac 2+ to protect this stainless steel outer part from galling and fretting and reduce the minimal allowable clearance (< 0.025 mm / 1 mil). Lunac 2+ can even be applied to small internal structures (+/- Ø 5 mm, length dependant). |

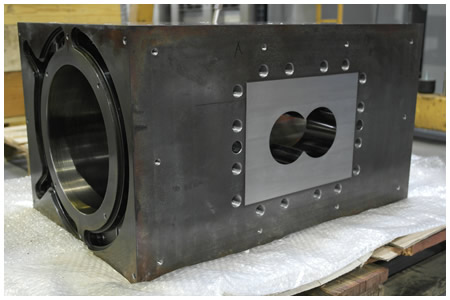

Besides Lunac 1 non stick coatings applied to the conveying canals of displayed screen changers, thick corrosion resistant Lunac 2+ coatings (75µm / 3 mil) are reliably applied to the mechanical (and/or corrosive) heavily loaded piston- and bore surfaces. This raised coating thickness proved to ban egg scale effects. Displayed nitrided parts (e.g. DIN 1.8519 or 1.8550) frequently developed galling scratches (and/or corroded) after a while.

A side effect of the Lunac 2+ non stick effect is that scales of hard thermally cracked plastic remnants will hardly or not build up between the piston and cylinder.

Picture:

(Nordson) Kreyenborg

Germany

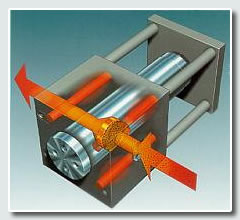

Vane pump: Stainless steel versions are known for suffering from sliding elements galling wear problems. Lunac 2+ applied to all sliding elements maintained the corrosion resistance and added the lacking galling resistance. This is an example of a principally poor, high wear system to be converted in a very durable and reliable system . |