Long lasting conservation of machine performance

Parts suffering from abrasive or erosive wear loads (such as wear rings, extrusion parts, cyclones or brass calibration parts, etc.) can very successfully be protected for high abrasive wear with Lunac 2+ semi (high) ceramic. This coating is very capable to deal with this kind of wear, by means of the combined |

hardness of Hv 1230 for the metallic glass and alloy matrix and Hv 2100 for the modified ceramic content. Additionally the coating can be applied locally, offers a wide thickness range (45-350 µm / 2-14 mil) and is dense. The process temperatures does not pass 310 °C |

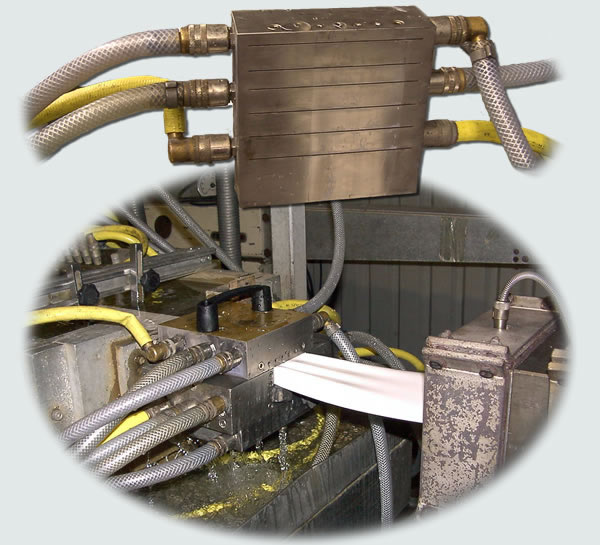

Lunac 2+ coated brass calibration plates operational in a process line for titanium dioxide filled PVC window profiles. Besides the wear resistance (see figure below), Lunac 2+ delivers products without any (black) spot or line anymore. The good heat conductance of these brass plates has not significantly changed. These parts last for at least 7 years in the case of intensive production instead of a few month. Moreover, only Lunac 2+ proved to offer enough friction reduction to proper product sliding.

These 2 calibration plates were tested under similar conditions (equal sleeve vacuum and product speed). The white product (TiO2) processed on the Lunac 2+ coated plate wears out the calibration plate 80 times slower than the original brass plate.

(Mainly PVC) extrusion calibers profit from

the hard wear resistant Lunac 2+ layer,

applied to brass substrates.

The service

time increases tremendously up to now

without any exception.

Frontal face of granulator plate is (100 µm / 4 mil) Lunac 2+ plated as a cheaper, but just as effective hard-metal replacement. |