The scratch resistant non-stick Lunac 1 coating highly reduces

pollution

of baking plates and sticking problems in food processing equipment

The non stick effect is the main reason for applying Lunac 1 coatings to dough baking plates and food processing machines. Besides this, the dense and corrosion resistant Lunac 1 structure prevents the surface from becoming 'impregnated' with degraded residues. Consequently, the often applied pyrolytic cleaning procedure followed by 'pre baking' is rendered completely superfluous. Lunac 1 non-stick coated plates are very durable compared to PTFE non-stick coated plates. In the case of a dough product manufacturer, using steel brushes on |

Lunac 1 instead of on mild carbon steel, baking plates experienced a wear rate of less than 0.03 mm (0.0012") in 5 years instead of 1.5 mm (0.059") in two years. Another important effect is the complete shielding effect of parts containing (lead)bronze or brass. Foods will therefore only contact food safe materials. Frequently the amount of oil used in dough processing can be reduced. The afore mentioned perfect bond between Lunac coatings and the substrate is crucial for the food industry, because flaking coatings are highly unwanted. |

New Lunac 1 coated waffle baking plate (left) compared to a new carbon steel baking plate (right). Pretty soon the steel baking plate will turn dark in production and suffer from increasing sticking problems. The wear rate due to the steel brush action is a multiple higher on the steel plates. Mostly, the return of investment proved to be less than a year.

New Lunac 1 coated waffle baking plate (left) compared to a new carbon steel baking plate (right). Pretty soon the steel baking plate will turn dark in production and suffer from increasing sticking problems. The wear rate due to the steel brush action is a multiple higher on the steel plates. Mostly, the return of investment proved to be less than a year.

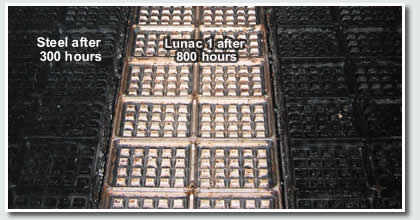

The non-stick and consequently anti-pollution effect of the Lunac 1 coating became very elusive on these test plates in dough baking process lines.

The requested steady product release from the upper plates became fully controllable due to the stable non stick effect of the Lunac 1 coated plates. Mild steel distance guidance blocks are Lunac 2+ plated to prevent this machine from wearing out too fast (+/- 54 times slower). When Lunac coated plates finally need a cleaning action (often 3 times later), this is significantly easier to accomplish.