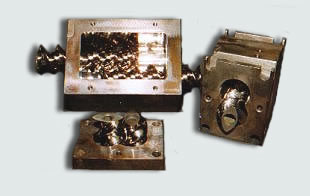

Lunac 1 coatings applied to screws and screw tips

The non stick effect of Lunac 1 coating on injection and extrusion screws is very interesting. The anti-black specks effect (see the picture on the Lunac 1 page) with especially polar plastics are until now almost unparalleled. The dense and corrosion resistant Lunac 1 coating is one of the very few materials that is durably able to withstand plastics which are capable to invoke a corrosive environment, such as ABS, PVC, PET, PC, HIPS or fluoroplastics. However, the most desired improvements are; a long lasting non stick effect and therefore melt flow / melt conveying improvement, the prevention of plastic degradation and reduction of screw cleaning. These effects are observed in +/- 85% of all cases. In the other less successful cases (normally with rubber based plastics) a temperature correction can still offer an improvement. There are some important points of interest before a screw can be coated successfully. Please contact our technical staff and/or see our report on the application of Lunac coatings in plastic processing machines. The feed back we received during more than ten years are bundled in a report on non stick and corrosion resistance experiences of Lunac coatings .