Lunac 2+ coated parts almost never return

for repair or revision

Four main Lunac 2+ version are available:

- Lunac 2+: wear, anti galling and cost optimised.

Usually 55-70µm (2.2-2.8 mil). In special cases

up to 250 µm (9.8 mil).

- Lunac 2(hc)+ duplex: ultimate corrosion

protection

capability, even after small accidents! Protects

parts long lasting from corrosion without any oil

film 120 µm (4.7 mil). EPQ qualified

- Lunac 2hc+: best chemical resistance.

Additional layer. See: Corrosion.

- Lunac 2rc: best wear resistance.

See: wear resistance

Examples

Dubai wheel bearings and storm lock systems are coated with Lunac 2+ because the Lunac 2+ coating offers a reliable bond, ultimate wear resistance and good corrosion protection. Lunac 2+ will wear out 300 times less than the composite bearing |

Main characteristics Lunac 2+ (duplex):

- This hard crack free coating is highly resistant to adhesive and abrasive wear (adhesive wear test results: 23 N at 0.7 m/s; the combination Lunac 2+/Lunac 2+ is 19 times more wear resistant than the combination of hardened (HRc 64-66) DIN 1.2379 on hardened DIN 1.2379. Wear resistance in most composite plastic bearing systems k= 0.04 E-9 mm2/N (composite plastic in this system: k=12 E-9 mm2/N).

- Virtually immune to galling / fretting / cold welding or seizing problems in non-lubricated conditions.

Therefore this coating is ideal for heavily loaded and non-lubricated parts in relative motion. - Lunac 2+ duplex has proved to be one of the most reliable corrosion protection systems in (sea)water.

- Often, wear of the non-coated opposing part is also significantly reduced, especially in sea water.

- The coefficient of friction is +/- 25% less compared to hardened steel DIN 1.2379 / 1.2379.

- Steel cylinders and rods coated with Lunac 2+ are practically equal to HVOF

ceramic plated cylinders with respect to wear, but are cheaper, much

less vulnerable and prevent high seal wear. - Able to deal with (shear) loads over 400 MPa with specified bearings.

- Although moisture can tarnish the Lunac 2+ surface,

Lunac 2+ coatings will not change its features. - Lunac 2+ highly resists oxidative wear (tribo wear).

- Complies fully with the RoHS standard.

- Relatively ductile (elongation 0.28%).

Ampelmann motion compensated gangways cylinders such as the arctic 'iceman' have been Lunac 2+ duplex coated to withstand the highly corrosive offshore (arctic) conditions. Lunac 2+ duplex eradicated any corrosion or wear issue. The good thermal conductivity of the semi-ceramic Lunac 2+ coating (combined with high tensile carbon steel) also reduces the seal temperatures which is important in the case of high velocity (wave compensation) systems. |

Thick complex Lunac 2+ coatings (80 µm / 3 mil) applied to screen changer piston and bores, offer one of the most successful tough ceramic-like, corrosion resistant alloy combination and are able to handle high mechanical loads and shearing without cracking or blistering.

|

Lunac 2+ duplex coated carbon steel parts in marine environment offer : |

- (galvanic and sub-surface) corrosion prevention due to the very dense, corrosion resistant structure with cathodic protective power and consequently resistance to corrosion after impact (see figure 5 !) |

- limitation or eradication of stainless steel and facilitating selection of high tensile steel |

- 4-fold improvement of heat conductivity and capability to select hard composite plastics. |

- ultimate scratch and abrasive (sand) wear resistance |

| - mostly highly profitable |

| Julianasluis Lunac 2+ duplex coated main bearing |

|

Stainless steel Rotor disk frontal face (above) or pump vanes and housing have been coated with Lunac 2+ to prevent wear, fretting and galling applied. The goal is hard metal replacement and chemical resistance. Lunac 2+ applied to a single moving element can already highly prevent the total system from galling. The service time of this concept vane pump dramatically increased. Picture and revision of vane pump: TDO technical services. |

Hydraulic crane piston rods coated with 120 µm (5 mil) Lunac 2+ duplex. These Lunac 2+ duplex coatings are particularly resistant to (sub surface) corrosion, scratches and high abrasive wear load. The new WMV 3900 mm plating line is able to handle parts up to 3000 kg (6667 Lbs). In 2017 the track record of Lunac 2+ duplex plated piston rods since the introduction in 2011 is 0.0005 return due to a crevice corrosion defect. Spontaneous corrosion has still never been claimed yet ! |

Corrosion resistance after damage

Lunac 2+ duplex coated parts can very well deal with impacts and

damage.

Lunac 2+ duplex will prevent the carbon steel parts from sub-surface corrosion in a unique way.

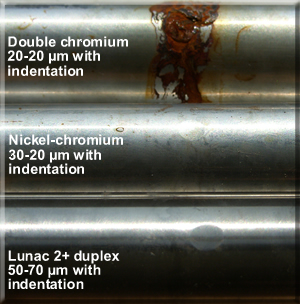

Test: 4 mild steel test rods with hard corrosion protection

coatings

after 1250 hours

neutral salt spray testing:

1- Double layer chromium mostly offers moderately up to good corrosion protection after 1000 hours NSS testing, but

cannot preserve corrosion resistance after a 0.08 mm / 3 mil plastic deformation has taken place. Chloride resistance is poor.

2- Nickel-chromium coatings frequently show some small rust spots after 1000 hours NSS testing, but do not

develop additional rust spots after a 0.08 mm / 3 mil plastic deformation has taken place. Chloride resistance is poor.

3- Lunac 2+ duplex can fully resist 2500 hours NSS testing and can deal with 0.08 mm / 3 mil plastic deformation.

Chloride

resistance is good.

4- Most HVOF ceramic duplex coatings (picture right) can fully resist 1000 hours NSS testing, but cannot deal with

almost any plastic deformation (progressive blistering).

Chloride resistance is mostly acceptable up to good.

| Details of the Lunac 2+ (duplex) coating system:

|

High mechanical load applications

Lunac 2+ (duplex) proved to be one of the most reliable and profitable coating systems to obtain long lasting wear, scratch and corrosion resistance. Lunac 2+ coated hydraulic cylinders and bearings in heavy lifting equipment are categorised as proven technology to withstand high shear loads and harsh outdoor conditions for a very long period (according to feed back, since 1995, no Lunac 2+ plated hydraulic cylinders is ever decommisioned due to spontaneous coating issues).

Basic elements :

- little seal and guide-band wear due to smooth surface

- no rust formation (and no sub surface corrosion)

ultimate scratch resistance and no oil leakage

ultimate scratch resistance and no oil leakage - accidents do not initiate a peeling process,

but are limited to localized deformations - able to deal with more than 400 MPa load

Enerpac and Mammoet cranes equipped

with Lunac 2+ coated hydraulic cylinders

and bearings.

The main bearing axles in the doors of the Kornwerderzand lock of the major northern Dutch IJsselmeer dam have been Lunac 2+ coated because of the corrosion resistance, exceptional abrasive (sand) wear resistance and shock resistance (waves) of the coating. Moreover the Lunac 2+ coefficient of friction in water contact conditions can be exceptionally low. |

Main Ø 280 mm submerged axles of the new buoy system in Rotterdam habour are Lunac 2 + duplex plated to resist corrosion and especially high wear loads (sand, sludge and continuous swing loads caused by the moored vessels at 3057 KN / 12 MPa bearing load). |

First inspection of main Lunac 2+ coated Ø 280 mm axle. Not any corrosion or

wear has been

recorded despite the brackish water and sludge/sandy condition at the bottom of the harbour.

Due to the non-stick characteristic of the Lunac 2+ surface the locally present sludge deposit can be removed

completely and with much less effort. The applied steel plate cannot damage the 135 µm / HRc 72 coating.